-

≤200mmFeeding Size

≤200mmFeeding Size -

65-720t/hProcessing Capacity

65-720t/hProcessing Capacity

5-100mm

It can crush more than 100 kinds of rocks. The common discharge size is...

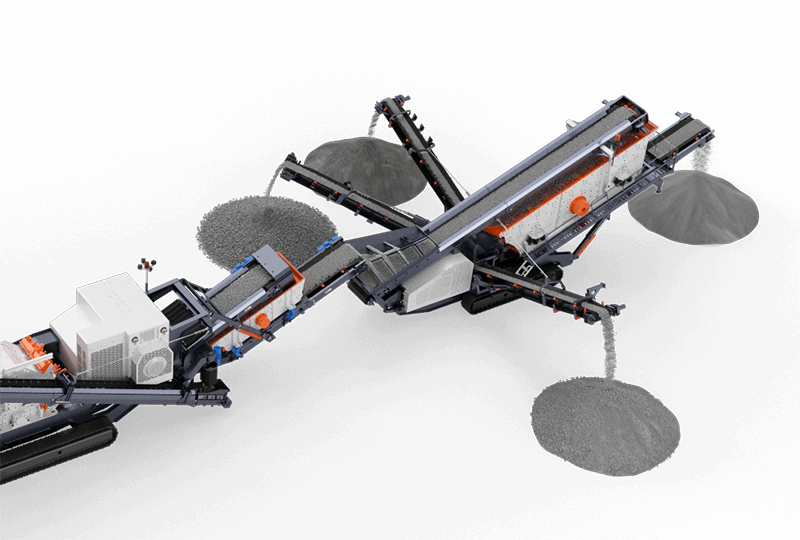

The material is transported to the crushing equipment through the belt conveyor, and the crushed material falls into the belt conveyor and is sent out. Qualified materials are either sent out from the hopper or stacked by the belt conveyor under the vibrating screen, and the unqualified large materials are directly sent back to the crushing chamber of the crusher for further crushing.

| Model | TS1860 | TS2160 |

| Screen Box | ||

| Shape(mm) | 1800x6000 Three-layer screen | 2100x6000 Three-layer screen |

| Feeding Size | ≤200mm | ≤200mm |

| Mesh Size | 5-100mm | 5-100mm |

| Drive Mode | Hydraulic motor drive | Hydraulic motor drive |

| Frame | ||

| Hydraulic Tracked Chassis | 40T | 40T |

| Boat Frame | Q345B Welding | Q345B Welding |

| Feeding belt conveyor | ||

| Specification | B1000*11.8m | B1000*11.8m |

| Drive Mode | Hydraulic motor drive | Hydraulic motor drive |

| Looped polyester canvas strap | EP-200-B1000x4(4.5+1.5) | EP-200-B1000x4(4.5+1.5) |

| First layer belt conveyor | ||

| Specification | B650*5.9m | B650*5.9m |

| Discharge Height | 2.8m | 2.8m |

| Drive Mode | Hydraulic motor drive | Hydraulic motor drive |

| Second layer belt conveyor | ||

| Specification | B650*7.5m | B650*7.5m |

| Discharge Height | 3.5m | 3.5m |

| Drive Mode | Hydraulic motor drive | Hydraulic motor drive |

| The third layer belt conveyor | ||

| Specification | B650*7.5m | B650*7.5m |

| Discharge Height | 3.5m | 3.5m |

| Drive Mode | Hydraulic motor drive | Hydraulic motor drive |

| Under the screen belt conveyor | ||

| Specification | B1000*8.5m | B1000*8.5m |

| Discharge Height | 3.6m | 3.6m |

| Drive Mode | Hydraulic motor drive | Hydraulic motor drive |

| Power System | ||

| Generator + transfer case + pump | 154KW Motor | 154KW Motor |

| Electrical System | ||

| Electric control cabinet | Engine running parameter monitoring, crawler walking, remote control of each belt conveyor, main electrical components Schneider. | Engine running parameter monitoring, crawler walking, remote control of each belt conveyor, main electrical components Schneider. |

| Hydraulic system | ||

| Various types of cylinders | Belt conveyor folding, vibrating screen lifting | Belt conveyor folding, vibrating screen lifting |

| Hydraulic Pumps, Valves, Accessories | Load Sensing, Electro-hydraulic Proportional Manifold | Load Sensing, Electro-hydraulic Proportional Manifold |

A: the product warranty period is 12 months since shipping date.

A: We have professional engineers abroad, after receiving your request, we will solve your problems at first time.

A: Our company can provide machine`s parts for your any time.

7-10 days for the stock, 15-30 days for the mass production.

30% deposit in T/T advance, 70% balance before shipment.

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.

Copyright © 2025 Henan Xianglong Machinery Equipment Co., Ltd.