It can crush more than 100 kinds of rocks. The common discharge size is ...

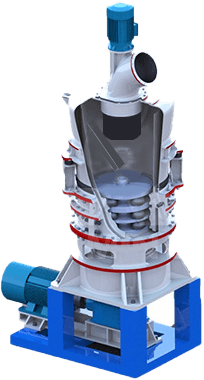

After hammer crushers break large bulky materials to smaller ones, elevator works to send materials to material bin. Next, materials are sent to the grinding mill evenly and they would fall onto the dispersing plate firstly. When the grinding mill runs, dozens of grinding rollers start to rotate and roll. Under the action of centrifugal force, materials on the dispersing plate are then thrown to the rim and drop to the grinding chamber. In the circuit, materials would be squeezed and ground. After being ground several times, materials are blown into the powder selector by airflow. Under the action of the impeller of powder selector, materials which fail to meet fineness would be sent back to grinding chamber to get another grinding while qualified powders would be collected by cyclone powder collector and discharged from the bottom as finished products. Some remaining powders would be collected by impulse dust remover and they may stick to the surface of filler-bag. So, next, high-pressure airflow controlled by the impulse valve blows the filler-bag to make it swell and shake violently. This sudden shake can help kick off materials on the filler-bag and collect them as finished products. After filtering, the airflow would be discharged to the air. This system adopts an open circuit and runs under negative pressure.

| Model | ZSM60 | ZSM80 | ZSM90 | ZSM100 | ZSM125 | ZSM168 | |

| Ring rollers(pcs) | 12 | 21 | 24 | 36 | 44 | 44 | |

| Working diameter(mm) | Φ600 | Φ800 | Φ900 | Φ1000 | Φ1250 | Φ1680 | |

| Number of grinding rings and raceways(pcs) | 1x3 | 1x3 | 2x4 | 2x4 | 2x4 | 2x4 | |

| Host speed(r/min) | 230-240 | 230-240 | 200-220 | 180-200 | 135-155 | 120-130 | |

| Maximum feed size(mm) | ≤10 | ≤10 | ≤20 | ≤20 | ≤20 | ≤20 | |

| Finished particle size(mesh) | 325-2500 | 325-2500 | 325-2500 | 325-2500 | 325-2500 | 325-2500 | |

| Capacity (kg/h) | 300-3000 | 500-4500 | 800-6500 | 1000-8500 | 2500-14000 | 5000-25000 | |

| Feeding machine | Type | Skirt belt feeder | Skirt belt feeder | Skirt belt feeder | Skirt belt feeder | Skirt belt feeder | Skirt belt feeder |

| Type | B300x60 | B300x60 | B300x60 | B300x60 | B300x80 | B400x80 | |

| Power(kW) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Host | Power(kW) | 45 | 55 | 45x2 | 132 | 185 | 315 |

| Powder separator | Power(kW) | 15 | 18.5 | 22 | 30 | 75 | 132 |

| Dust collector | Type | DMC96 | DMC160 | LDCM35-7 | LDCM35-8 | LDCM72-8 | LDCM72-8x2 |

| Power(kW) | 37 | 45 | 55 | 75 | 132 | 220 | |

| Discharge screw | Power(kW) | - | 3 | 3/5.5 | 7.5 | 7.5 | 7.5x2 |

| Discharge valve | Power(kW) | 0.75x2/0.75x1 | 0.75x1 | 1.1x1 | 1.5x1 | 1.5x2 | 1.5x2 |

| Air compressor | Power(kW) | 7.5 | 11 15 | 15 | 22 | 37 | 55 |

| Gross weight(t) | 12.5 | 16.5 | 24.6 | 32.2 | 54 | 76 | |

| Dimensions(mm) | 12000x4500x6000 | 14000x4700x6200 | 14700x4800x8600 | 18000x4600x8600 | 14000x9000x10250 | 26300x7500x11900 | |

A: the product warranty period is 12 months since shipping date.

A: We have professional engineers abroad, after receiving your request, we will solve your problems at first time.

A: Our company can provide machine`s parts for your any time.

7-10 days for the stock, 15-30 days for the mass production.

30% deposit in T/T advance, 70% balance before shipment.

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.

Copyright © 2025 Henan Xianglong Machinery Equipment Co., Ltd.