Email: [email protected]

Email: [email protected]

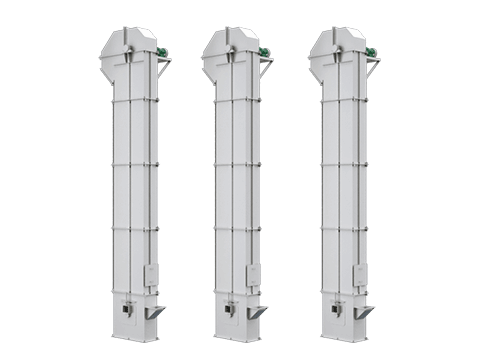

small, medium and large models are in stock available

Feeding Size: <75mmProcessing Capacity: 7-500m³/h

Hot modelTDG500 typeNE100NE300

Output sizedifferent sizes for 120 kinds of stones

20-30mm

10-20mm

5-10mm

0-5mm

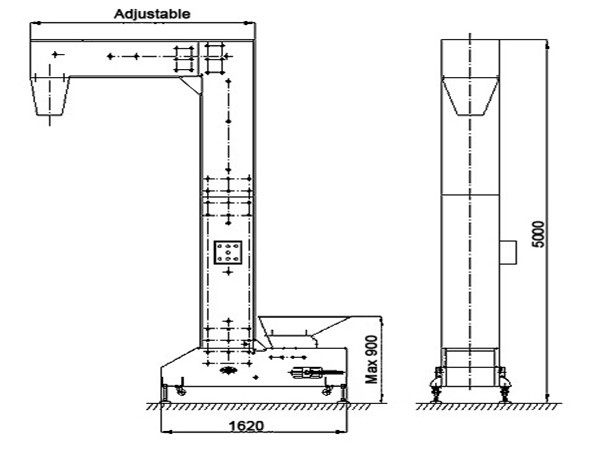

This elevator has the advantages of big conveying amount, high elevating height, stable and reliable operation and long service. Its main performance and parameters conform to the JB3926----85 Vertical Bucket Elevator (this standard equivalently refers to international stand and foreign advanced standard), and the hauling round-link chain conforms to the MT36----80 Mine High Strength Round-link Chain.

This elevator is suitable for elevating powdery, granulate and small-sized non-corrosive materials such as coal, cement, stone, sand, clay and ore. Since the hauling device of the bucket elevator is circuit chain, it is allowed to elevate the materials with relatively high temperature.

1. The driving power of bucket elevator is small, and it adopts in-flow feeding, guiding discharging and large-capacity hopper. When the materials are elevated, there is almost no returning, so that the reactive power is small.

2. Bucket elevator had wide elevating ranges. This type of bucket elevator has few requirements for the types and property of the materials and it can not only elevate general powdery and granulate materials, but elevate materials with high corrosion, and what is more, it has fine sealing performance and little pollution.

3. Bucket elevator has stable and reliable operation. Advanced designing principle and processing method ensure the reliable operation of this machine and the trouble-free time exceeds 20,000 hours.

4. Bucket elevator has long service life. During the designing process, the designers make sure that there is almost no materials scattering in the feeding and discharging process, thus reducing the abrasion of the machine.

The materials are scooped up by the hopper and brought to the top along with the conveyor belt or conveyor chain, and then the materials will roll down after bypassing the top wheel, and the bucket elevator will pour the materials to the receiving chute. The driving belt of bucket elevator with driving belt often uses rubber belt which is installed on the upper or lower transmission drum and the upper or lower redirection transmission drum. Bucket elevator with chain drive is often installed with two parallel transmission chains, and there is a pair of transmission sprocket on the lower or upper part and a redirection chain wheel on the upper or lower part. Bucket elevator is often installed with enclosure to avoid dust pollution.

chain belt elevator technical parameters

| Model | Lifting height(m) | Delivery volume(m³/h) | Material max size(mm) | Bucket distance(mm) | Motor Power(kw) |

| TH160 type | 25 | 7-12 | 15-20 | 400 | 3-4 |

| TH200 type | 28 | 8-15 | 20-30 | 500 | 3-5.5 |

| TH250 type | 30 | 10-25 | 25-35 | 500 | 4-7.5 |

| TH300 type | 30 | 25-35 | 30-40 | 500 | 5.5-11 |

| TH315 type | 40 | 30-40 | 35-45 | 512 | 5.5-15 |

| TH400 type | 40 | 45-60 | 40-55 | 512 | 11-22 |

| TH500 type | 40 | 65-80 | 50-60 | 512 | 15-30 |

| TH630 type | 40 | 100-120 | 60-65 | 688 | 18.5-37 |

| TH800 type | 40 | 130-150 | 65-75 | 920 | 22-45 |

Steel wire belt elevator technical parameters

| Model | Lifting height(m) | Delivery volume(m³/h) | Material max size(mm) | Bucket distance(mm) | Motor Power(kw) |

| TDG160 type | 80 | 34 | 0-20 | 2.6 | 2.2-11 |

| TDG200 type | 80 | 45 | 0-25 | 4.1 | 3-15 |

| TDG250 type | 80 | 71 | 0-30 | 6.5 | 5.5-22 |

| TDG315 type | 80 | 101 | 0-35 | 10 | 7.5-30 |

| TDG400 type | 80 | 158 | 0-40 | 16 | 15-45 |

| TDG500 type | 80 | 218 | 0-45 | 25 | 18.5-55 |

| TDG630 type | 80 | 345 | 0-50 | 40 | 30-90 |

| TDG800 type | 80 | 491 | 0-50 | 61 | 45-132 |

Apron chain elevator technical parameters

| Model | Lifting height(m) | Delivery volume(m³/h) | Percentage allowed(%) | Pitch(mm) | Motor Power(kw) | ||||

| 10 | 25 | 50 | 75 | 100 | |||||

| Material max size(mm) | |||||||||

| NE15 | 40 | 16 | 65 | 50 | 40 | 30 | 25 | 101.66 | 1.5-4 |

| NE30 | 59 | 31 | 90 | 75 | 58 | 47 | 40 | 152.4 | 2.2-7.5 |

| NE50 | 62 | 60 | 90 | 75 | 58 | 47 | 40 | 152.4 | 3-15 |

| NE100 | 58 | 110 | 130 | 105 | 80 | 65 | 55 | 200 | 7.5-30 |

| NE150 | 65 | 170 | 130 | 105 | 80 | 65 | 55 | 200 | 11-37 |

| NE200 | 73 | 220 | 170 | 135 | 100 | 85 | 70 | 250 | 18.5-75 |

| NE300 | 61 | 320 | 170 | 135 | 100 | 85 | 70 | 250 | 22-75 |

| NE400 | 47 | 420 | 205 | 165 | 125 | 105 | 90 | 300 | 45-90 |

| NE500 | 58 | 500 | 240 | 190 | 145 | 120 | 100 | 300 | 45-132 |

Copyright © 2025 Henan Xianglong Machinery Equipment Co., Ltd.